The Prox-Eye Vehicle Guidance System, developed by Correct-AI in Edmonton, Alberta, can dramatically improve the safe operation of large, complex industrial vehicles by eliminating blindspots, providing an audible hazard warning and even identifying slope roll and pitch angles.

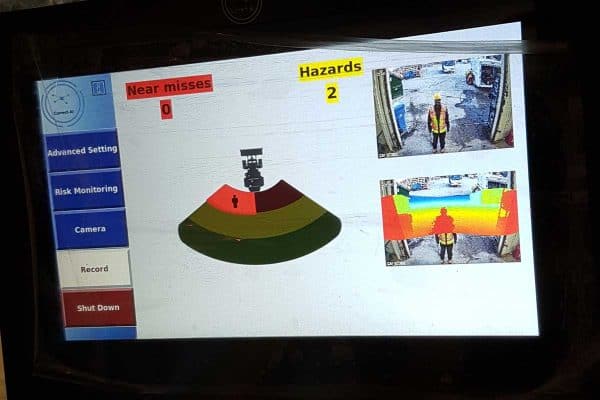

The technology combines an HD camera (equipped with infrared for night time) LiDAR (light detection and ranging) sensors and proprietary AI technology in a powerful proximity awareness system. In-cab monitors provide equipment operators with real-time hazard identification and audible warnings of potential obstructions or hazards. The system is specifically designed to eliminate blindspot hazards in heavy equipment such as hydraulic excavators, pipe-layers and large loaders.

To learn more, we spoke with Branden Modin, of Correct-AI:

“The LiDAR sensors produce about 240,000 laser points per second,” said Modin. “They develop a field of vision and are able to map anything that could be unseen within the operator’s blind spot. They can even classify hazards as human, a vehicle or a general obstacle. This data is then processed in real time to identify true threats and eliminate false alarms.”

The Prox-Eye system has been in development since early 2020, and has already undergone field trials and improvements. Correct-AI now believes it to be the most precise object detection technology, with the ability to eliminate false alarms, enhance operator capabilities, and improve safety on even the most challenging worksites. It is already a fixture on several oil and gas sites, and has even been designated the most innovative equipment by a Tier 1 contractor.

Prox-Eye Dual System is just one example of the leaps and bounds being taken by Canada’s pipeline operators and their suppliers in their quest for zero incidents and maximum sustainability. Stay tuned for future ‘Technology Spotlight’ posts in which we will explore more of the innovations moving us toward the pipeline industry of the future.